Fatigue in the Aircraft Maintenance Environment

Our goal with this Fatigue in Aircraft Maintenance Environment feature is to showcase our knowledge and expertise for the benefit of our readers. We’ve been serving a vast roster of aviation industry clients for more than 60 years – and we are looking forward to sharing various key lessons learned with you. Our Insights series will offer best practices and gained know-how, practical guidance and advice, and will help educate and inform in various areas of interest to our aviation community as we move forward. Please don’t hesitate to reach out with comments and feedback at insights@execaire.com so that we can serve you better.

As far back as 1997, the NTSB recommended that the Federal Aviation Administration “Review the issue of personnel fatigue in aviation maintenance; then establish duty time limitations consistent with the current state of scientific knowledge for personnel who perform maintenance on air carrier aircraft. (NTSB, 1997)

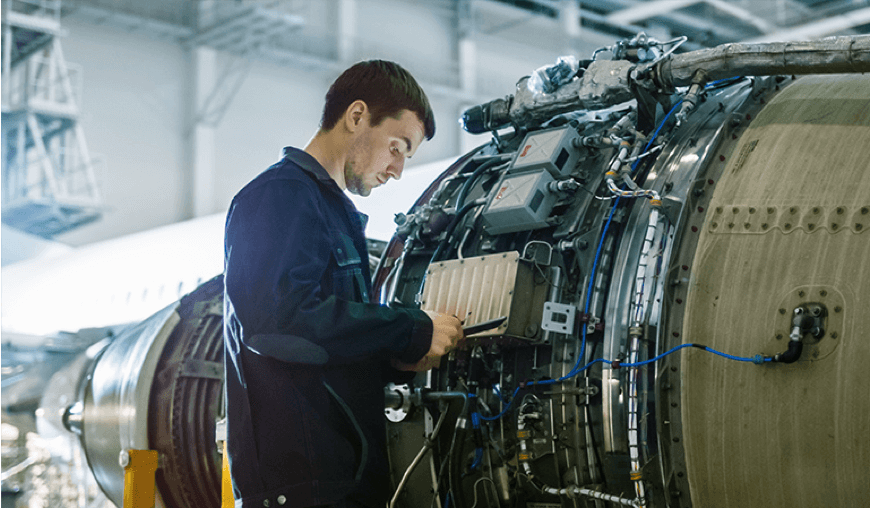

Maintenance personnel fatigue is a serious issue and certainly top of mind for IEAG’s Director of Maintenance George Zarikos, who points out that fatigue risk management has typically focused on continuous control tasks, such as operating an aircraft, with falling asleep being the main threat.

“From a maintenance perspective, sleep (or a micro-sleep), is not the threat—but rather errors caused by impaired mental functioning, such as FOD left in an engine, missing steps in a repair process, unsecured access panels/ cowlings, fitting of wrong parts, etc., all of which could have serious consequences.”

Fatigue Risk Management Systems

The FAA, ICAO, EASA, Transport Canada, and others have promoted Fatigue Risk Management Systems. Although the FAA established the initial Human Factors for Aviation Maintenance training in 1988, it took a major tragedy to bring about greater interest from regulatory bodies. As such, regulatory bodies have not yet mandated measures for fatigue management among aircraft maintenance personnel, though many organizations, including Execaire Aviation, feel this is a necessary next step.

This leaves maintenance organizations responsible for implementing their strategies, be it via an existing Safety Management System (SMS) or through a stand-alone Fatigue Risk Management System (FRMS) The FAA has defined FRMS as a data-driven and scientifically-based process that allows for continuous monitoring and management of safety risks associated with fatigue-related error. It is part of a repeating performance improvement process. This process leads to continuous safety enhancements by identifying and addressing fatigue factors.

What are the contributing factors to fatigue?

As Zarikos points out, “Risk of fatigue resides in nighttime work and rotating shift work along with the possibility of long and unregulated duty times. This, coupled with the resulting in sleep disruption and cumulative sleep deficit, leads to impaired judgment, difficulty focusing attention, memory lapses, reduced mood and motivation, and other effects on performance. Ultimately, the cause of fatigue is a combination of elements, related to both the work environment and personal factors.”

When asked about what an effective FMRS should cover, Zarikos states that “An effective RMS encompasses company policies, incident reporting, analysis, proactive risk assessment, and open communications between employees and management contributes to a culture of safety.”

At Execaire Aviation, our FRMS model calculates positive points for rest and negative points for fatigue within a 24-hour projected window for specific maintenance jobs. The summary calculation of the fatigue factor takes into account commuting times when the request came in for additional work and the maximum number of straight hours that can be worked.

“If the model gets to a positive number that mitigates the fatigue factor at its maximum, then the work can continue. If not, we send the person home to rest,” Zarikos explains. Through the development of Execaire Aviation’s FRMS, Zarikos, and his team have identified some of the root causes of fatigue and how those causes can lead to maintenance errors. One was ensuring that shift lengths are eight hours and anything beyond that requires special consideration and

evaluation, while the second was making it mandatory to declare entering an area of fatigue.

Managing Fatigue in Aircraft Maintenance

“It’s a question of adopting fatigue management as an element of our culture,” says Zarikos. Execaire Aviation put its FRMS in place for two main reasons: to build a holistic safety culture and to ensure best-in-class manpower planning. “We have an in-depth understanding of how fatigue factors influence performance—and we leverage that understanding to improve safety,” he explains.

Zarikos notes that although some airlines have begun to account for fatigue in their maintenance personnel, this is not an across-the-board adjustment for all aircraft owners, operators, and airlines. “But it is the right thing to do and something the regulatory bodies should make mandatory. There’s no other option,” he says. “We already know that shift work presents its specific challenges, so we’ve learned how to manage that alongside challenges like unexpected workloads, clients with drop-in demands and aircraft-on-the-ground (AOG) work.” Here, Zarikos refers to the complex matter of shift rotations, which already interfere with the body’s acclimation to patterns. Unexpected work can throw off even the best-laid plans, having the potential to keep maintenance crews on duty many hours beyond their shifts, resulting in profound fatigue that could cause aircraft maintenance errors.

“Our industry is based on cross-pollination – for safety especially. We all learn from each other. While we wait for the regulatory bodies to make managing fatigue in our environment mandatory, we hope that other companies will follow us on the path of fatigue measurement and prevention. We can only evolve by collecting more data and then together, we can create an even more robust FRMS for maintenance – for everyone.”